Best Electret Masterbatch Suppliers

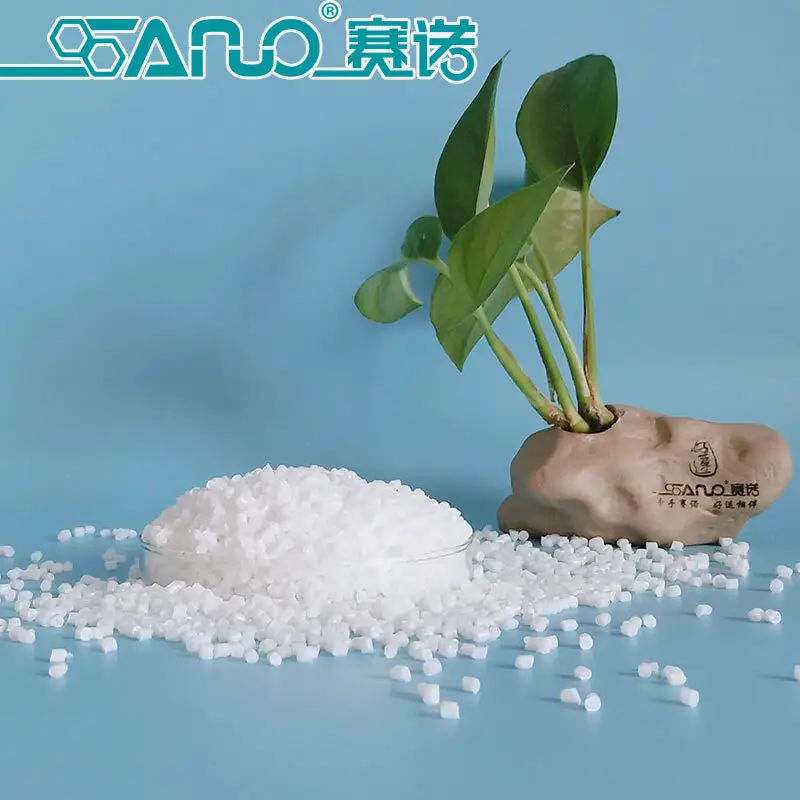

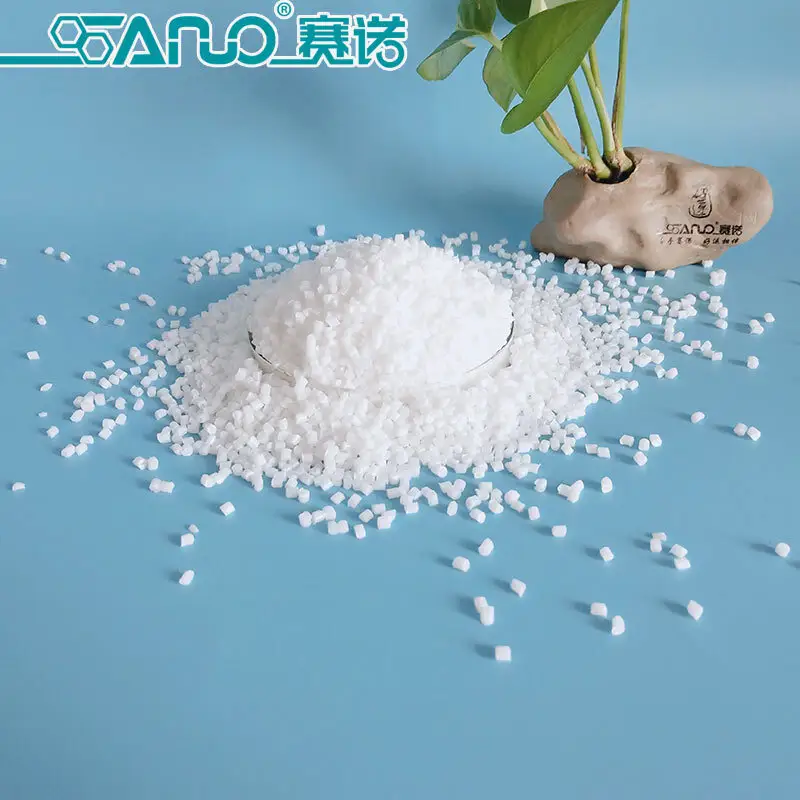

Electret Masterbatch description

The product features high efficiency. It is able to perform tasks at a high speed and is capable of delivering results within short periods of time.

Electret Masterbatch SPECIFICATIONS

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person : Amy

Tel : +86 532-87655918

Tel : +86 532-87655918

Phone: +86 18765238781 / 18253251580

E-mail : sales@qdsainuo.com

E-mail : sales@qdsainuo.com

Whatsapp/wechat/sky : 18765238781 / 18253251580

Address : Biulding No 15,Torch Garden Zhaoshang Wanggu, Torch Road No. 88,Chengyang,Qigndao,China

Address : Biulding No 15,Torch Garden Zhaoshang Wanggu, Torch Road No. 88,Chengyang,Qigndao,China

Superior Quality, Excellent Service!

Contact us for additional information or to explore partnership opportunities.

Call Us

+86 18765238781