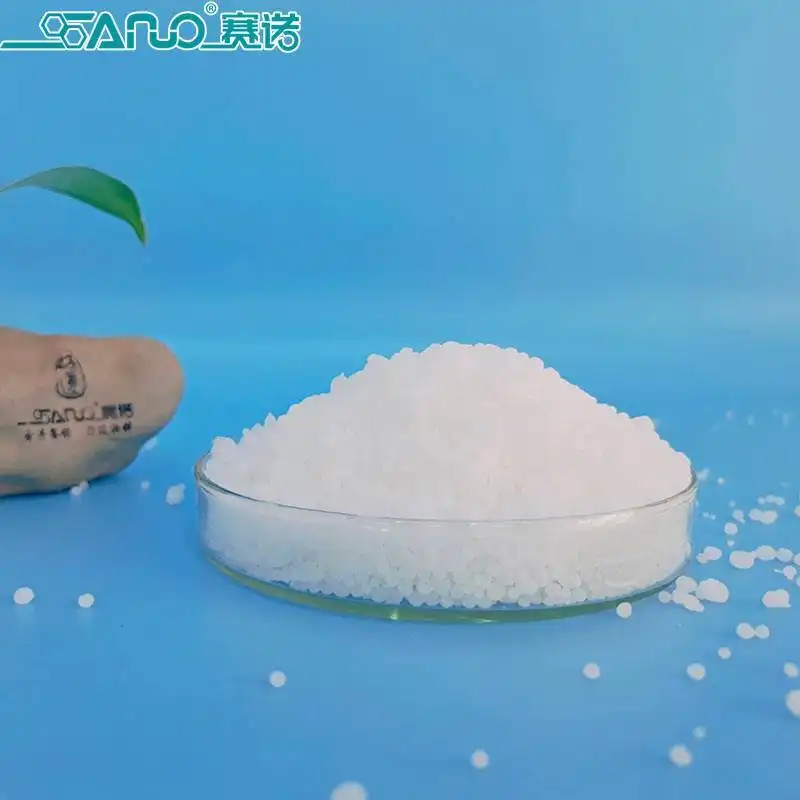

Low density oxidized polyethylene wax OPE wax

Products Feature

1. Enhanced Dispersibility: The oxidation process introduces carboxyl groups, improving the dispersibility of the wax in various systems, leading to better dispersion of pigments and additives.

2. Improved Rheological Properties: OPE wax can modify the rheological behavior of formulations, enhancing flow properties, reducing viscosity, and improving sag resistance.

3. Surface Modification: It enhances surface slip and anti-blocking properties, leading to smoother surfaces and reduced blocking issues in coatings and films.

4. Compatibility: Oxidized polyethylene wax exhibits excellent compatibility with various polymers, making it a versatile additive for a wide range of applications.

5. Thermal Stability: Low-density oxidized polyethylene wax offers good thermal stability, making it suitable for applications requiring resistance to high processing temperatures.

PRODUCT ADVANTAGE

In PVC system, low density oxidized polyethylene wax can be plasticized ahead of time, and the later torque is reduced. It has excellent internal and external lubrication.

It can improve the lubricity between polymer and metal.

It can improve the dispersion of colorants.

Give products good transparency and luster.

Better improve production efficiency

INDEX

Property | Index |

Softening Point ℃ | 100-105 |

Viscosity CPS@140 ℃ | 200-300 |

Acid Value | 15-20 |

Appearance | Granule |

APPLICATION

1. Color masterbatch:Low-density oxidized polyethylene wax is often used as a dispersant and lubricant in color masterbatch formulations. It helps improve the dispersion of pigments and fillers, leading to enhanced color consistency and improved processing efficiency.

2. PVC products:Low-density oxidized polyethylene wax can be used as a lubricant, processing aid, and release agent in PVC processing. It improves flow properties, reduces melt viscosity, and enhances the release of finished products from molds.

3. Wax emulsion (emulsification) :Low-density OPE wax can be emulsified to form a stable wax emulsion, which is used in various applications such as coatings, flooring, and textiles. The emulsion provides improved surface properties, water resistance, and flexibility.

4. Modified material:Low-density oxidized polyethylene wax can be used as a modifier in various materials, including thermoplastics, elastomers, and adhesives. It can enhance properties such as impact resistance, flexibility, and adhesion, while also providing improved processing characteristics.

CERTIFICATE

The products have been approved by FDA,REACH,ROSH,ISO and other certification, in line with national standards.

EXHIBITION

Every year we go around the world to participate in various large exhibitions, you can meet us in every domestic and foreign exhibitions.

Looking forward to meeting you!

FACTORY

Sainuo is a comprehensive high-tech enterprise integrating production, scientific research, application and sales.

QUICK LINKS

PRODUCTS

CONTACT US

Tel : +86 532-87655918

E-mail : sales@qdsainuo.com

Address : Biulding No 15,Torch Garden Zhaoshang Wanggu, Torch Road No. 88,Chengyang,Qigndao,China

Superior Quality, Excellent Service!

Contact us for additional information or to explore partnership opportunities.

+86 18765238781